How to make CBD packaging comply with local regulations?

Regulatory compliance is the first step in CBD packaging design. Most regions require child-resistant packaging that meets federal standards for oral CBD products (such as oils and gummies). They must also carry warnings such as “Not for use by persons under 18.” CBD labeling requirements vary significantly across countries and regions.

In the United States, you need an FDA disclaimer, ingredient list, and THC content labeling.

In the EU, CBD concentration and origin labeling are required, and some countries require bilingual packaging.

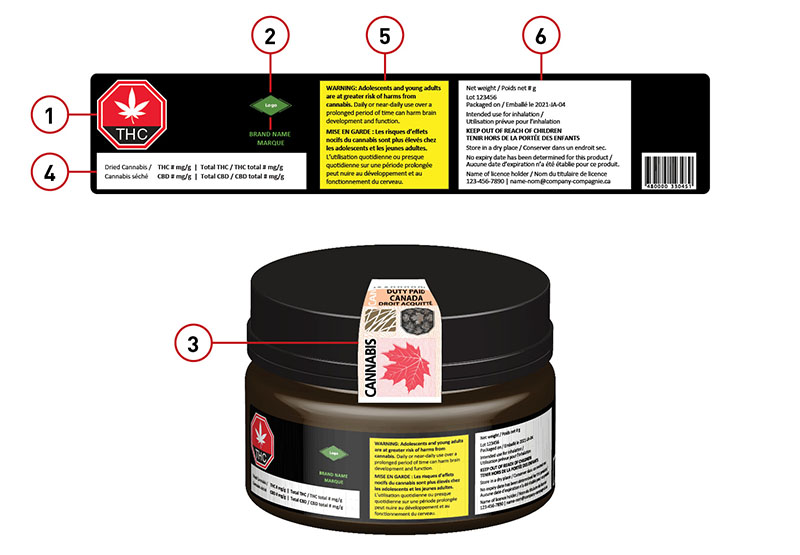

Canada’s Cannabis Act implements plain packaging requirements for some CBD products.

📌 Practical Tip: Before designing your packaging, it’s best to fully understand local laws and regulations and organize your designs and copy. If you’re still unsure, reserve 25%-30% of the packaging space for regulatory text to avoid rework.

Key regulatory references by region

| Region / Country | Requirements | Label Language | What It Means for You |

| USA | FDA disclaimer, THC content, child warning | English | Improves compliance and avoids legal risks |

| Europe | CBD concentration, origin, health claim restrictions | Multiple languages | Facilitates cross-border sales and reduces reprinting risks |

| Canada | Plain packaging rules, standardized font size | English + French | Prevents product removal due to non-compliant packaging |

Practical tips and advice for brands

- Check regulations before exporting: Carefully review the CBD compliance requirements of the destination country.

- Consult a lawyer before designing: Consult a local lawyer to ensure that the printed content is complete.

- Keep blank areas: to facilitate quick adjustments to legal texts.

Case study: A US CBD gummy candy brand failed to reserve regulatory space. After printing was complete, they discovered they needed to add a second foreign language: French. This resulted in all boxes being scrapped and reprinted.

For more information on CBD labeling regulations, please refer to the CBD product labeling guide.

What Types of CBD Packaging Boxes Are Most Popular in the Market?

Common CBD packaging types include dropper boxes, gummy candy packaging, e-cigarette liquid boxes, and ointment jars. Popular styles include folding cartons, drawer-style gift boxes, and child-resistant zipper bags.

- CBD tincture boxes: Protect glass bottles from light and damage

- CBD gummy packaging: Block moisture, maintain taste, and extend shelf life

- E-liquid packaging boxes: well sealed and leak-proof

Popular Packaging Types & Benefits

| Package Types | Material | Features | What it means to you |

| Folding carton | 350–400gsm SBS | Lightweight structure, flexible printing | Reduces shipping costs |

| Drawer Gift Box | Greyboard + Art Paper | Premium look, ideal for CBD gifts | Enhances brand image |

| Protective Zipper Pouch | Metallized PET or Kraft laminate | Moisture-proof, oxidation-resistant | Extends shelf life |

What materials work best for CBD product protection and shelf life?

CBD products are susceptible to degradation due to sunlight, oxygen, and moisture. When selecting materials, consider their barrier and storage capabilities.

- Amber glass: blocks UV rays, suitable for CBD oil

- Metalized PET: Suitable for soft candies or snacks

- Kraft + foil laminate: environmentally friendly and moisture-resistant

📌 Practical advice: Conduct ASTM F1980 testing (an industry standard for evaluating the performance and integrity of packaging under accelerated aging conditions) to ensure that the effectiveness does not decrease by more than 10% after 6 months.

How to design CBD boxes that attract and convert customers?

- Use natural colors (green, brown, beige) and environmentally friendly visuals to convey natural and organic concepts.

- Add functional designs such as child-resistant covers, tamper-evident seals, and moisture-proof structures.

- Simple design, using minimalist design and clear fonts, detailed labeling of ingredient list, efficacy, traceability code, etc.

Case study: A British CBD oil brand increased its conversion rate by 18% through Pantone spot colors + texture technology.

What printing and finishing options make CBD packaging stand out?

- Low migration ink: suitable for food contact CBD packaging

- Pantone spot colors: Keep greens and browns vibrant and long-lasting

- Eco-friendly soy ink: recyclable, biodegradable, environmentally friendly

How to ensure CBD package is eco-friendly and sustainable?

- FSC certified cardboard

- Compostable film

- Avoiding non-recyclable mixed composites

How to balance cost and quality in CBD packaging production?

- Simplify the box design and reduce the subsequent processes such as hot stamping and embossing

- Material mix (high-strength outer layer + economical inner layer)

- Batch orders to reduce the frequency of startup

What mistakes should you avoid in CBD packaging design?

- Failure to comply with local regulations, such as lack of childproofing, safety seals, or inaccurate disclosure of THC content

- Insufficient material barrier capacity

- Lack of anti-counterfeiting and traceability elements

- Not tested for transport drops

- The package is difficult to close, causing inconvenience to your users

The latest CBD packaging trends in 2025

- Blockchain traceability: Improving transparency and trust

- Child protection standardization: retailers’ acceptance is more stringent

- High barrier environmentally friendly materials: balancing sustainability and performance

- Green and environmentally friendly materials: such as recycled paper and kraft paper, reducing carbon emissions

FAQs

Why is packaging important for CBD sales and compliance?

Packaging not only protects the product but also determines whether it can enter the market and win the trust of consumers.

Which printing method is best for CBD packaging boxes?

Low migration ink + Pantone spot color is most suitable for long-term display and food grade safety.

How to make CBD packaging both legal and attractive?

Use textured craftsmanship and brand colors within a compliant framework, taking into account both regulations and aesthetics.

What is the best way to ship CBD products?

Use a hard inner tray + an outer box that has passed the ISTA 3A drop test.

Conclusion

CBD packaging must strike a balance between regulatory compliance, product protection, visual appeal, and sustainability.

Start with regulatory research, select materials and designs, and finally ensure testing so your CBD products are safe, legal, and marketable.

Contact us to get a customized CBD packaging solution, ensuring your design complies with the regulations of your destination country.

About XiangGe Package

We specialize in custom CBD packaging boxes and have experience in regulatory compliance design, a full range of barrier material testing capabilities, and environmentally friendly material options.

Our production system has served more than 100 brands worldwide, helping your new product packaging meet your expectations.