Why Film Tension Matters More Than You Think in Resin Printing

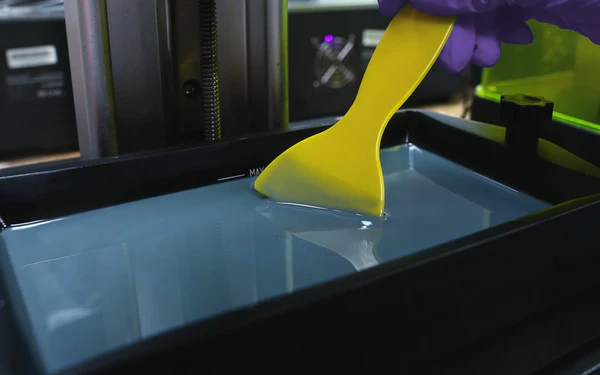

When your print with a resin printer fails, the first suspect is the resin type or slicer setting. However, the resin film could be one of the leading causes of a print failure. But how? When there’s irregular film tension, it tends to stretch, and once the tension isn’t correct, it can cause warping, layer misalignment, poor surface, and in rare cases, print failure.

But why exactly does film tension matter, and how can we get the perfect tension without over- or under-stretching the film? In this blog, we’re covering every aspect of film tension, why it matters, and how you can ensure that you’re working on the optimal setup.

The Basics of Film Tension: Physics & How it Works

When you use a resin printer and start the process, the printer cures a layer. That’s where the build plate lifts a little to peel it away from the release film, a process known as peeling. When film tension is processed, you get an overall equal and predictable force across all the points.

However, there’s an issue. When the peel force is too loose, the film starts to sag, causing the surface to become uneven. This can produce distorted prints, especially in the center, where the sag will affect the most.

On the contrary, when the tension is too tight, the film will be put under extra stress. Moreover, the printer’s Z-axis mechanics will also suffer from it. In both conditions, the rate of distortion has increased dramatically.

Proper tension holds the print in its place, and if it’s not done right, the whole print can fall off.

Print Quality & Layer Accuracy

Film tension affects the layer flatness during the curing process. Consider this example. Let’s say that your film is sagging. This means that the center of the layer is now lower compared to its edges—even less than 0.5 mm height difference can cause a mess, including:

- Blurred details in the text or your prints.

- Poor layer adhesion on large surfaces.

- Micro gaps between layers ultimately lead to weak spots.

Loose tension also causes something like the elephant’s foot to occur. This occurs because the resin pools are slightly thicker in the center during actual exposure.

Film Longevity (And Wear & Tear)

The unevenly tensioned films wear out much faster than the regular ones. When there’s inconsistent stretch, certain areas will get more press stress than the others, leading to a plethora of issues like cloudiness where tension is weakest, microtears, and loss of optical clarity.

There are numerous online forums, but a properly tensioned PFA film can last around 30-50% longer than poorly tensioned ones when printed under the same conditions. So, by evenly providing tension to the film, you are also saving money while ensuring that there are fewer disruptions.

Resin Waste

Incorrect tension is also a silent resin waster. You will be shocked to learn that a print failure due to a layer shift requires all resin in the vat to be filtered before reuse. So, if the tension isn’t correct, large failed prints can result in up to 30 to 60 mL of resin waste in one go.

However, the even bigger cost is electricity and time loss. Longer prints can easily take up to 12 hours, and that would take a huge toll on your productivity and morale. Therefore, resin waste is one of the huge issues that occurs due to incorrect layer tension.

Measuring and Maintaining Film Tension

Now that we know all the issues that film tension can add up, here’s a complete tutorial on how to measure and maintain your film tension.

Professional labs have tensiometers to get those exact numbers, but if you don’t have access to the tool, here are some of the things you can try on your own:

- Tapping: Tap the film slightly, and you will see that it will produce a sharp sound that sounds like a drum. If that sound doesn’t happen, then there are chances that the film is undertensioned.

- Sag Checking: You should look at the film. If it stays flat without any visible sagging under its own weight, then it’s good to go. However, if there’s a sage, then there’s an issue.

- Frame Alignment: Sometimes, the vat frame is not assembled evenly, which causes the pressure to not be complete on all sides of the film. So, you can check visually there as well.

After doing these three tricks, you should have a complete idea of how to measure the film tension. But how do you maintain it?

Why Chitu Systems’ Quick Release Resin Vat is a Game Changer

Quick-release vats like Chitu Systems Hoopat Resin Vat fix all the film tension-related issues. Manually changing or screwing down the film takes a lot of time, and there is always a chance of producing uneven tension.

With the quick-release vat, you solve this issue by:

- Applying even pressure across all sides at once.

- Drastically reducing film installation time to just under 1 minute.

- Maintaining tension consistency after multiple changes.

Moreover, the Hoopat Quick Release Resin Vat is also fully metal and corrosion-resistant, making its structure solid and reliable. Ultimately, you can fix all your film tension-related issues with a cheaper, thinner, and reliable frame vat.

Final Verdict

Film tension is a minor detail in 3D printing. But in the long run, not only is it the most overlooked factor that affects print quality, but it also ruins the print itself in some cases. Whether you’re a hobbyist or running a resin print business, a quick-release resin vat can help you.

Moreover, if you’re looking for more 3D printing accessories, check out Chitu Systems’ wide range of accessories.